I'm feeling a little better today. But, I feel like I can't stop pulling that snowballing frustration thread just yet...

In case it wasn't crystal clear, although things were getting 'done'...What started as a little ball of frustration continued growing as it collected flakes rolling down my hill of projects to complete before the weather breaks.

After getting the T-Top fixed and the windows adjusted(again) we had a couple of decent short drives.

That's when a noise coming from the right rear of the car either got much worse or just sounded much worse because most of the other noises are gone. With a couple of long road trips planned for this season, I decided we needed to address the RR axle (and related wheel wobble). The noise and what I thought was an intermittent wobble from the right rear started after an unintentional off-road excursion the weekend after my 21st birthday. After some research, it seemed like a relatively simple, and not too expensive project.

I purchased this replacement axle from Dutchman Axles:

IMG_5672

IMG_5672 by

Tom Sherer, on Flickr

I chose Dutchman simply because they had a specific PN cross-referenced with the stock PN I found in the '76-81 Pontiac Parts guide' (RR Axle GM PN: 1263988). Dutchman indicates that their 'stock replacement' axle (PN 'SR #63) is made of a higher quality metal alloy and more splined area. I don't know about all of that, but it IS straight and shiny.

Altogether, with the lugs installed and bearing & Seal included the parts were $180.00.

Replacing the axle is supposed to be a relatively simple job.

BUT

Step one: Remove the wheel. On the first step I found that one of my lugnuts had was cross-threaded the last time it was

installed. Not a big deal. The new axle has new studs, but the lugnut itself was hosed: Add Lugnuts to parts list.

Step two: Remove the brake caliper. Well...The top caliper bolt would not back out. It just kept turning and turning! WTF?

I still don't quite understand what happened but something looking like a washer was in-between the backing

plate and the caliper. Whatever it was was metal, and the caliper bolt was threaded through it. I assumed it was

some sort of threaded insert that should be living pressed into the caliper where the caliper bolt passes through.

But, there is no pressed in thread insert in that inside caliper bolt hole?! I don't know where this thing came

from, or how it got there, or where it's supposed to live but it was turning with the caliper bolt and not allowing

the bolt to back out. Ultimately I was able to get needle nose vice grips in there to hold it while we unscrewed

the caliper bolt.

With the caliper off the rotor, the inside brake pad came apart! The pad's backing plate just came divorced from

the pad! WTF!

Two steps in, and I have two new parts to order and a caliper problem to investigate.

Rolling right along...

We got the cover off, no problem.

IMG_5681

IMG_5681 by

Tom Sherer, on Flickr

Next to come out is a bolt that retains the pinion shaft which goes through the middle of the Diff side gears. Remove this little bolt...

IMG_5683

IMG_5683 by

Tom Sherer, on Flickr

I wanted to be careful with that little retainer bolt, so as not to break it off in the pinion shaft.

I used my small 1/4 ratchet ...Surprise, surprise...not much resistance and the bolt came right out. Phew!

BUT...The Pinion shaft wont pull out? Feels like it's hitting something?!

After closer inspection, I found...The retaining bolt HAD broken off inside the pinion shaft.

At this point, I figured I'm screwed! I'll need to buy a new Diff center section, get the car towed, pay someone to install it. OR I could order a whole new rear end and just drop it in myself?! Neither being a cheap option.

UGH!

But, here's the happy ending!

The next night I had a closer look into the hole where the other half of the bolt/pin still lived. My little magnetic picker-upper chumpy was exactly small enough to fit into the hole deep enough to feel the end of the bolt left inside. And, when I twisted the magnetic chumpy I could see the broken half of the bolt was spinning freely...It was backing out as I turned the magnet! Turns out the retainer broke right on the very last thread...

IMG_5683

IMG_5683 by

Tom Sherer, on Flickr

Not sure how it broke -there- where it was still turning freely, but whatever! It backed out no problem! And, the pinion shaft dropped right out!

Phew!

The next step amazes me...That pinion shaft keeps the axle from moving inward. With it out of the way you can push the axle in towards the center of the diff to expose the c-clip that keeps the axle from moving outward. In the pic below you can see it, partially falling out on the right side of that 'S' shaped spring, against the spider gear on the right.

IMG_5688

IMG_5688 by

Tom Sherer, on Flickr

The C-Clip slides right out and you can remove the axle. Crazy that's all that holds the axle in, but it works I guess.

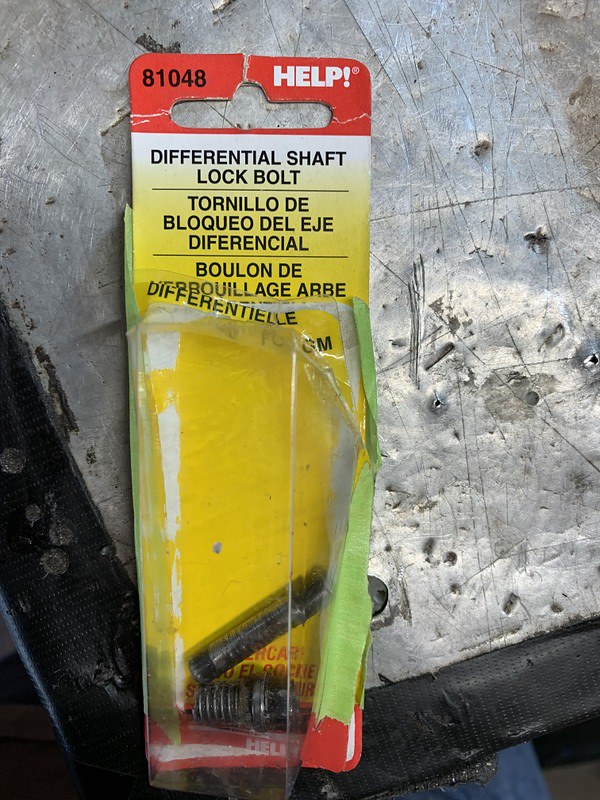

Things were looking up! So, we made a parts store run to rent the axle-bearing puller tool. This is where it gets REALLY crazy...Julie just happened to find a replacement retainer pin on the shelf at the parts store!

IMG_5701

IMG_5701 by

Tom Sherer, on Flickr

I was excited, things are finally going our way! I even found real-life professional, bearing and seal installation tools from a defunct GM dealership. They were used, and cheap, but best of all they were local. I could just stop by and pick them up! The rental tool worked perfectly to remove the bearing and seal:

IMG_5691

IMG_5691 by

Tom Sherer, on Flickr

IMG_5690

IMG_5690 by

Tom Sherer, on Flickr

And the bearing and seal installation tools made easy work of installing the new ones. With those in place the new axle slid right back in place!

With everything back together I took the car for a short drive around the neighborhood to make sure everything back there would stay together. WOW. I didn't realize how much noise that rear was making, or how much vibration it introduced into the car until it was fixed. The car cruised and coasted more smoothly and quieter than ever!

I went back home to pick Julie up for a longer shake-down ride.

Julie on-board we made it literally one mile down the road when....Bing...

WTF NOW!?!

P0171 + P0172 'Too Lean' Bank One & Bank Two.

These are the same codes that I couldn't solve back when we first got the LS1 on the road. Right before my trip to drop the car off in TN for body and paint. Back then I had to take the car to a tuner to get them cleared out.

UGH!

The snowball started picking up speed (and more flakes of frustration) again.

Soldiering on to try to figure out the 'too lean' codes we started looking at the fuel system. I decided to drop the gas tank (for like the 84th time) to re-install the fuel pump the car was happy with last summer. (I had swapped that Accell FP out for a Walbro pump earlier this winter. Because A) I had the (presumably) higher quality Walbro pump on hand and B) The sending unit seal was leaking). Since that's the only thing in the fuel system that has changed, it seemed like a good place to start.

Out to the garage to get things arranged to pull the tank. I fire up the car to bump it forward a few inches so we have room at the rear and SMACK-SMACK-SMACK-SMACK! The f'ing AC compressor starts making an awful, loud 'whacking' sound!!!!

WTF! NO WAY!!! I mean...Listen to this...

https://www.youtube.com/watch?v=T6tk0wqZSs8Now we are going through the fuel system for the Lean codes, and are in touch with Vintage Air tech support about the AC Compressor noise. I don't want to jinx anything, but I think we might've found the cause for one of those problems.

So as not to look like a total idiot unnecessarily I'll have to keep you in suspense while I figure out whether or not I'm right.

Thanks again for listening to my rants. It is therapeutic for sure!

Take care guys.

-Tom