With the ECU mount sorted out, I was determined to get the wiring buttoned up. While it's great that Holley provides a clean harness with lots of length to route where you need it, for me it was way too much length. I tried looping it around, and started going down that path, then realized that I really disliked how it looked and was in the way of future components. So I pulled it all back out and started over. After a few different options, I found that looping around behind the ECU and looping around the passenger side, it routed much better and used up all of the "extra" length in the Holley harness. Once that was straightened out, I could build off of that routing and start wiring up my Bussmann fuse/relay panel. I pre-wires as much as I could on the bench, then I brought it into the cabin to integrate.

I added wires to relays and spots for future fused accessories that I may need. I added three relays; the bottom one will be a relay dedicated ignition relay to power the panel, middle relay is my neutral safety switch that gets a feed from the factory 4L80e switch. The top relay is a transmission relay to separate it from the engine ECU ignition. It's in the instructions that they need to be separated or the engine may not shut off, but when I opened my transmission harness there was no relay. I found that I must have had an older transmission harness that only had a power feed and that Holley revised the later harnesses to include a relay.

Here is a picture in the middle of my wiring mess. I built the ECU mount and harness in a way that I could pull out the Bussmann panel for servicing, so you can see it on the glove box door. Then I tested everything and it worked perfectly!

Now that it's working I can put it all together and start to tidy up the under dash wiring.

I still have several wires that need to be terminated, but overall I'm happy that the wiring is mostly complete. Most of the remaining wiring is related to my turn signals, gauges or radio. I also wired in a hidden kill switch as a bit of extra protection.

Now that the wiring for the engine/trans is in place and fully functional, I continued down my list to figure out what else I needed to do in order to fire up the car...again I did a bunch of misc. things like, filling the trans fluid, looping cooler lines, re-routing some wiring in the engine bay, final mounting the radiator, installing engine steam ports, tightening bolts, reinstalling O2 sensor, and much more. I got it to the point that I was able to fire up the car as a complete assembly for more than just a few seconds. While the tune needs a lot of work, I was happy to report that it ran with great oil pressure and didn't have any engine leaks that I could find. I did have one transmission cooler line that was dripping quite a bit, but that should be a pretty quick fix. Since this was a completely unknown transmission, I put jack stands under the rear end with 10 quarts in the transmission. My neighbor stopped over when he heard the car fire up and shifted into reverse and he said the wheels were turning! Then in park they stopped.

https://youtu.be/5noolvlV4Ck?si=1xMyT9sw32TpJa7_I'm very pleased that the car is mostly back together now and the motor will run and start with the key as well as move the wheels in gear. I was however disappointed with the way the engine was running. After some more diagnosis, I've got some fueling issues that need to be sorted out. It will only build about 10psi with the fuel pump on, engine off. Then when the pump stops, the pressure drops to zero. I need to so more diagnosis before I can find a solution. Guessing that it's the Frankenstein fuel pump that I built.

Moving on, I wanted to get the brakes sorted out. I had hoped to just bleed the rear brakes and call it a day, but the driver's side bleeder was froze shut. Ran down to the parts store and ordered a short section of NiCopp and two new wheel cylinders. Pretty cool that they had these on the shelf for an almost 70 year old car!

Pulled off the driver's side and everything had surface rust, but was in pretty good shape functionally. Not sure what all of the oil is on the axle? If it was a wheel cylinder, I would have expected to see it on everything?

Was able to pop off the top springs and pop the old cylinder right out. Luckily the brake fluid hadn't made it's way down this far yet, so there wasn't any fluid to worry about. Routed the line over the axle housing, then cut and flared to meet up with the hose.

Then it was rinse and repeat for the passenger's side. There was a bit more fluid on this side, but overall no much mess. That project was one of the few times when it took about the same time as I expected which is rare. In a way I'm glad the bleeder was froze because now I have new wheel cylinders and confirmed that everything is in working order.

Next thing I had to address was something I discovered after welding in my transmission crossmember a few weeks ago. Two pieces of weld spatter landed on the NiCopp lines and welded themselves in place?!? I didn't think that it was possible since they are mostly Copper, but apparently there's enough Nickle in them to have mild steel weld spatter stick. So rather than replacing the whole thing, I opted to just add a union fitting. I'd love to say that this was also a mostly clean job like the wheel cylinders, but that was not the case at all. I tried to quickly get my flare tool in there, but as fast as I was working the fluid just gushed out.

I bought these little clamps a few years ago, and this was just the ticket after I got a good flare. They are made by SUR & R Auto and are called brake fluid stoppers and were perfect for this situation.

I was able to take my time on the other flare since not much fluid came out. Once that was good, I added the union fitting and tried to quickly tighten it all. Got it all tightened down and it didn't drip once overnight, so I call that a win.

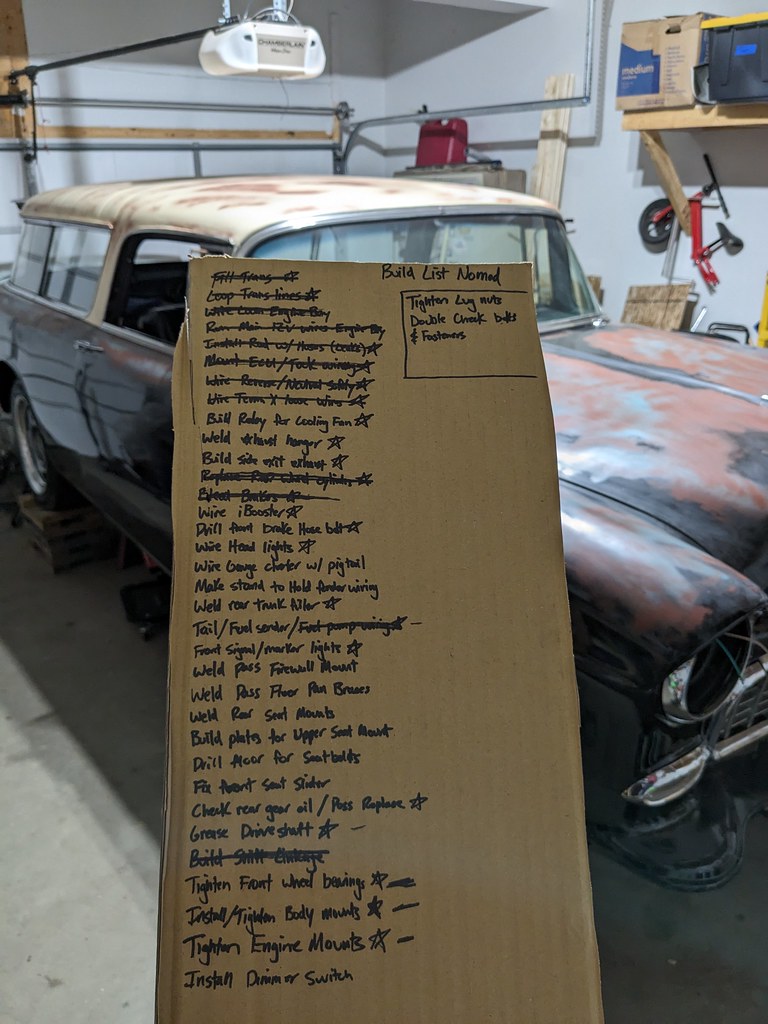

I'm pretty quickly crossing things off of this list! Once I cross a few more off of the list, I think I'll take it up and down the block.

It was a fairly lazy Sunday yesterday so my wife said that she could give me a hand bleeding my brakes. They bled out really nicely after only a few open/shuts on each bleeder. Tested them and the pedal is rock hard. I'm hoping to hook up the iBooster this week and see what the assist feels like. If I can figure out the fueling issue this week, I'm nearly ready to see what she does on the street.

Cheers,

Ryan